Comparing Natural and Synthetic Quartz Sand: What is the Difference

Comparing Natural and Synthetic Quartz Sand: What is the Difference

In contemporary surface design, engineered quartz materials have become the canvas of modern interiors—sleek, durable, and visually versatile. But beneath the polished finish of every quartz slab lies a less visible yet critical element: the quartz sand. Whether you're a material-conscious architect or a sourcing director seeking stable quartz surface supply, understanding the distinction between natural quartz sand and synthetic quartz sand is key to both aesthetic and technical decision-making.

1. Natural Quartz Sand VS Synthetic Quartz Sand

1) What Is Natural Quartz Sand?

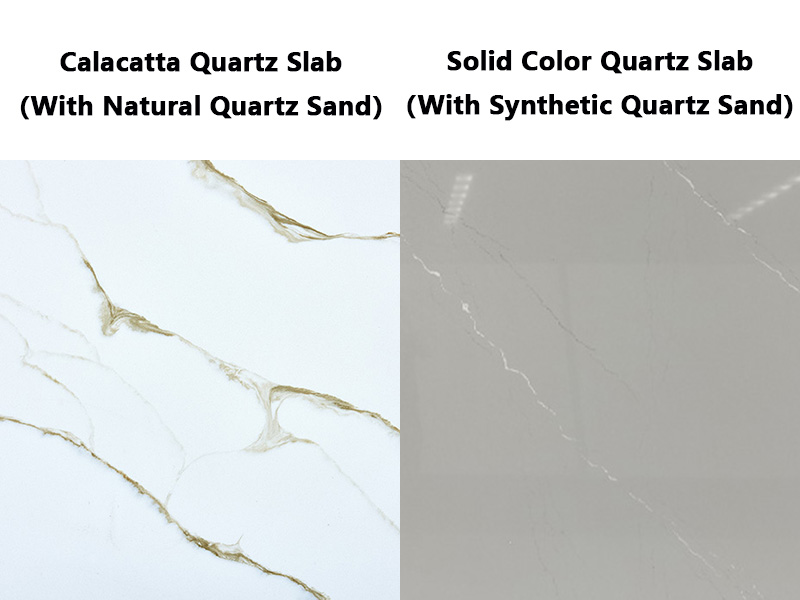

Natural quartz sand is derived from crushed quartz rock, typically mined from quarries and then washed, sorted, and refined. This type of sand is commonly used in the production of quartz sand for slabs that aim to replicate the look of natural stone.

Advantages:

High hardness and durability

Organic, non-repetitive textures

Warmer undertones with more natural variation

Disadvantages:

Less color uniformity between slabs

Potential for trace impurities

Less control over whiteness or tone consistency in engineered quartz materials

2) What Is Synthetic Quartz Sand?

Synthetic quartz sand is produced via high-temperature processing or chemical synthesis. It’s engineered to provide maximum purity and consistency—ideal for minimalist designs or pure white surfaces.

Advantages:

Exceptional color consistency and brightness

Fewer inclusions or mineral variations

Better suited for large-scale quartz surface supply projects

Disadvantages:

Higher production cost

Slightly more brittle texture compared to natural sand

May lack the natural "depth" of organic patterns

Performance Comparison in Engineered Quartz Slabs

| Feature | Natural Quartz Sand | Synthetic Quartz Sand |

|---|---|---|

| Color Stability | Medium – varies with source | Very high – controlled in lab |

| Veining Appearance | Natural, more random | Uniform, consistent |

| Cost | Generally lower | Higher due to processing |

| Suitable Design Styles | Classic, stone-like patterns | Minimalist, ultra-white, terrazzo-style finishes |

| Role in Quartz Surface Supply | Common in stone-mimicking collections | Preferred in modern, clean design applications |

3. Applications in Design: Where Each Sand Excels

Natural quartz sand is often found in engineered quartz materials that mimic the irregular beauty of stone—perfect for kitchen islands, fireplaces, or spa-like bathroom vanities. Its natural flow pairs effortlessly with wood, metal, and matte finishes.

Synthetic quartz sand, meanwhile, anchors the modern interior: seamless countertops, glossy commercial walls, and large-format flooring where uniformity is essential. It is frequently used in high-volume quartz surface supply chains for residential developers, prefab cabinetmakers, and luxury retailers.

Quartz Sand Types & Their Common Slab Applications

| Quartz Sand Type | Common Slab Applications | Key Characteristics |

|---|---|---|

| Natural Quartz Sand | Marble-look quartz slabs (e.g., Calacatta, Carrara) | Organic texture with natural mineral variation |

| Soft-toned, vintage-inspired surfaces | Offers subtle color shifts and depth | |

| Boutique custom slabs for residential and art-focused spaces | Suitable for nature-inspired or premium designs | |

| Synthetic Quartz Sand | Solid color quartz slabs (e.g., Pure White, Jet Black) | High purity and consistent color tone |

| Modern minimalist and industrial-style slabs | Excellent for achieving a sleek, clean finish | |

| Extra-large format slabs or ultra-thin engineered quartz panels | Reliable strength and dimensional control in high-volume manufacturing |

4. Design Strategy: Choosing with Intention

For architects and interior designers, the choice between natural and synthetic sand should align with both the sensory goals of a space and its functional demands.

Want subtle variation and tactile depth? --Natural sand delivers.

Need crisp brightness, batch control, or consistent pigmentation? --Synthetic sand is your ally.

For wholesalers, the consideration expands to logistics—supply consistency, cost structure, and client profile. In both cases, understanding the backbone of your quartz surface supply opens new possibilities for creativity and confidence.

About Us

With over 30 years of experience in the stone industry, we operate as an integrated manufacturer and exporter, backed by self-owned quarries and a complete quartz surface supply chain. Yeyang Stone offer flexible production solutions tailored to client needs—whether it’s color control, material ratio, or performance balance.

Our focus is on delivering reliable, customizable engineered quartz materials for projects of all scales. Let our expertise support your design and procurement decisions—professionally, precisely, and consistently.