Precision in Motion: Inside Yeyang Stone CNC Automatic Polishing Process

The Power of Precision Drive: Unveiling our CNC Automatic Polishing Process

In the highly competitive quartz stone industry, it is not only the material itself that determines the quality of the product, but also the fineness of the surface treatment. In order to achieve a higher standard of countertop texture, our factory has introduced an advanced CNC quartz slab polishing system, which guarantees that every piece of quartz surface is smooth, even and durable by intelligent means, and truly achieves the double sublimation of craftsmanship and aesthetics.

Fully-automatic operation, more uniform surface effect

Our CNC quartz slab polishing line is equipped with a programmable multi-head system that controls every step of the process, from rough grinding, to fine grinding, to mirror polishing, in a precise and programmable manner, with little or no human intervention. Compared to traditional manual polishing, this system regulates speed, pressure, and head paths more accurately, resulting in a highly consistent gloss and flatness on every quartz surface, regardless of human error or batch variation.

(Yeyang Quartz Factory CNC Automatic Polishing Process Machine)

Flexibility to adapt to different sizes and textures

The CNC quartz slab polishing system automatically adjusts the parameters to match different slab sizes, thicknesses and edge finishes, whether it's a standard specification or one of our specialty Super Jumbo quartz slabs. This not only makes it easy for us to respond to customized orders, but also improves the efficiency of mass production. Even for complex textures or formulations with a high mineral content, the CNC machine is able to precisely control and ensure that each polished quartz slab has a natural, uniform texture.

(During CNC Automatic Polishing Operations)

Precision meets efficiency

Automation allows us to increase efficiency while reducing reliance on labor, operator fatigue and errors. Through a highly stable control program, we are able to ensure that each polished quartz surface is flat and free of ripples, scratches and brightness variations. The system sets the optimal path according to different quartz surface formulations, ensuring that every inch of the surface is polished evenly.

(Finished CNC Automatic Polishing Operations)

Green Manufacturing with Energy Efficiency

As part of our sustainable manufacturing strategy, the CNC quartz slab polishing line also excels in energy savings. It consumes less electricity and water per unit area than traditional methods. At the same time, our factory is equipped with a closed water recirculation system and dust collection equipment to realize a more environmentally friendly production model, and to make the entire quartz surface processing environment cleaner and safer.

The beauty of craftsmanship begins with a smooth surface

Whether it's for the kitchen, commercial space or bathroom, our automated machining process is behind the luster and flatness of every piece of polished quartz. This high standard of CNC quartz slab polishing is not only the last step in the process, it's a reflection of our commitment to quality.

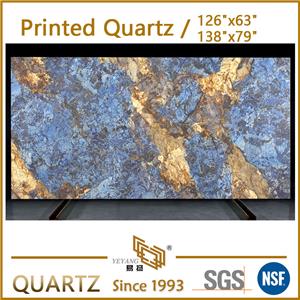

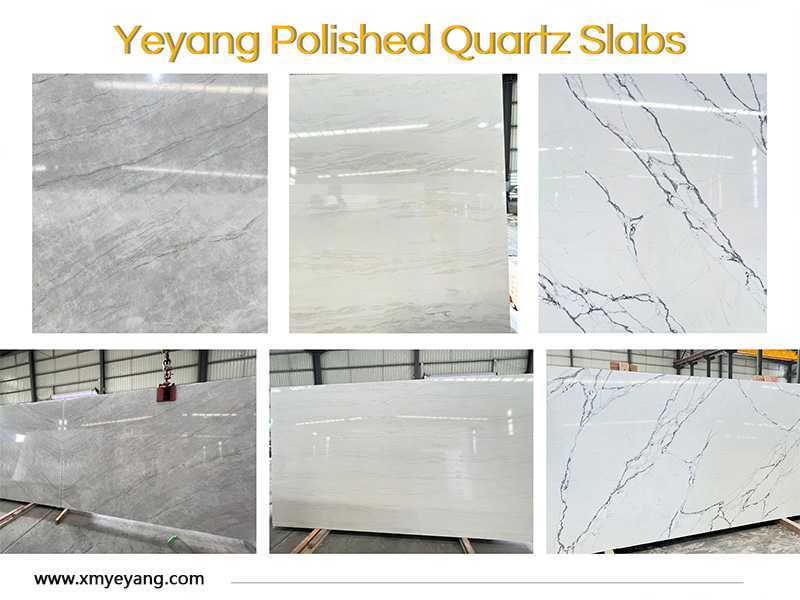

(As shown below, from left to right are Printed Quartz Taj Mahal, Carrara Quartz B4094, and Super Jumbo Quartz Calacatta B4071)

In Yeyang Quartz factory, each quartz slab is not just a product, but a commitment to detail - polished quartz of truly high quality through an intelligent control system that gives each piece of quartz surface a unique texture and vitality.

👉Reach out to our team now to request a sample and experience the exceptional polished quartz quality firsthand.