Practical Guide: Tips to Prevent Cracks in Quartz Countertops

| Practical Guide: Tips to Prevent Cracks in Quartz Countertops

Quartz countertops are a popular choice in kitchens and commercial spaces due to their durability, scratch resistance, and elegant appearance. Made primarily from 92% quartz sand combined with 8% resin, pigments, and other additives, quartz slabs undergo vacuum pressing, vibration, curing, and polishing to create a high-density, hard, and stain-resistant surface. They are heat-resistant to an extent, non-porous, corrosion-resistant, and safe for direct food contact.

However, from a physics perspective, quartz has slight thermal expansion and contraction, and certain mechanical properties such as tensile strength, impact resistance, and fracture toughness. When the material is exposed to extreme temperature changes, uneven stress, or strong impacts, quartz countertop cracks can appear. Understanding how to prevent quartz cracks and maintain proper care is key to prolonging the life of your countertop.

1. Common Causes of Cracks in Quartz Countertops

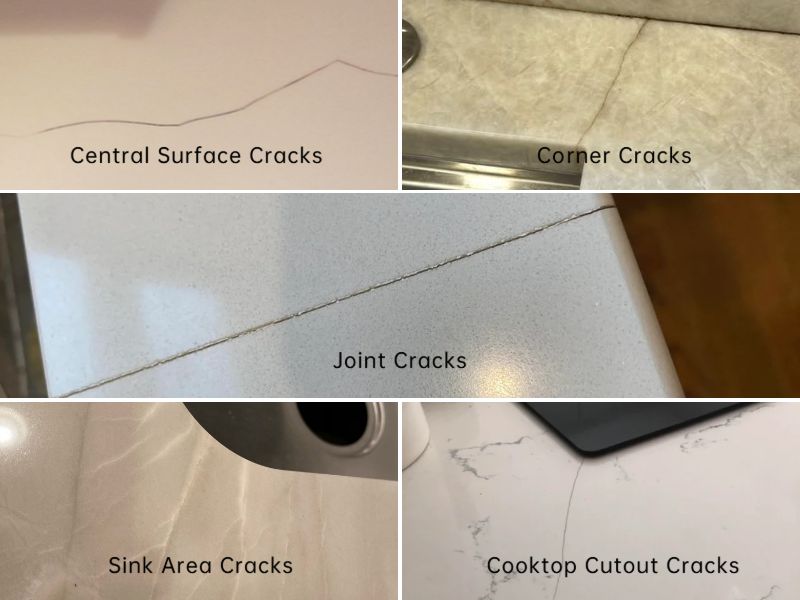

Center surface cracks – Often caused by high heat, heavy impact, uneven cabinets or support boards, or hidden defects within the slab.

Corner cracks – Occur when countertops are tightly fitted against walls without expansion gaps, when cabinets are uneven, or due to uneven contraction caused by temperature changes and impact.

Around sinks – Cracks may form if the sink cutout has no buffer, rough edges, or if the countertop contracts unevenly under temperature changes or impact.

Around cooktop openings – Can happen if the stove is installed too tightly, cutout edges are rough, or the countertop experiences uneven thermal expansion.

Backsplash-to-counter joints – Weak adhesive bonding can lead to separation and cracking.

Countertop seams – Misaligned seams, uneven adhesive application, or excess curing agent can make joints brittle, causing cracks under minor impacts.

Knowing these common causes is the first step in learning how to prevent cracks in quartz countertops and maintain their pristine condition.

2. Installation Tips to Prevent Quartz Cracks

Proper planning and installation are crucial for preventing quartz cracks:

Plan seams wisely – Avoid placing joints at corners or near cooktop openings. Consider the material’s thermal expansion and stress distribution when selecting seam locations.

Round corners – All countertop corners should have a radius of at least 25mm to reduce stress concentration and prevent corner cracks.

Proper cutouts – Keep cutout edges at least 80mm from the countertop edge and maintain a minimum radius of 25mm at corners.

Expansion gaps – Leave 2–4mm gaps between the countertop and walls to allow for thermal movement. Support boards should be spaced no more than 600mm apart to reduce deformation and quartz countertop cracks.

3. Daily Use Tips for Maintaining Quartz Countertops

Even with proper installation, following these tips for maintaining quartz countertops can prevent cracks caused by external factors:

Avoid striking the countertop with heavy objects.

Do not place extremely hot pots or pans directly on the quartz surface—always use heat pads or trivets, especially on light-colored quartz.

Avoid sudden impacts or excessive pressure that could exceed the material’s strength.

By taking these precautions, you can significantly reduce the chance of quartz countertop cracks and ensure your countertop remains beautiful and functional.

Following these practical tips will help you prevent quartz cracks, maintain a flawless appearance, and extend the lifespan of your countertop. For minor damage, quartz countertop repair can also restore its look, but prevention is always the best strategy.

Explore our high-quality quartz slabs for kitchens and commercial projects. Contact us today to discuss bulk orders and export options.