Yeyang Quartz Factory Dispatch — B4094 Super Jumbo Quartz Slabs Shipment

Yeyang Quartz Factory Dispatch — B4094 Super Jumbo Quartz Slabs Shipment

Recently, Yeyang Quartz Slab Factory has been preparing a batch of export quartz slab orders. This shipment consists of model B4094 super jumbo quartz slabs in the size of 3500×2000mm, produced for a customer in Orlando, Florida. It is also our third super jumbo quartz slab order shipped this quarter.

(Yeyang B4094 Super Jumbo Quartz Slab 3500mm*1500mm)

What Is a Super Jumbo Quartz Slab?

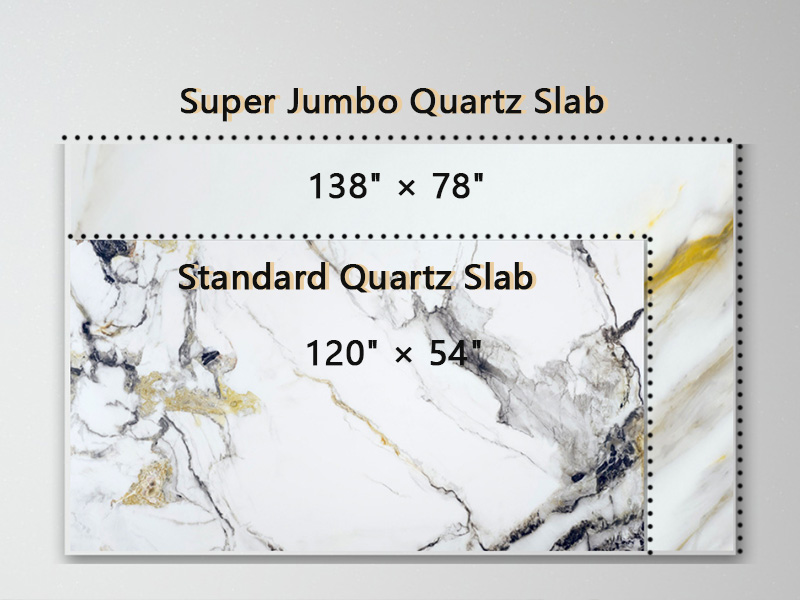

Standard quartz slabs are typically 3000×1400mm (about 10 ft × 4.5 ft), while super jumbo quartz slabs reach up to 3500×2000mm (about 11.5 ft × 6.5 ft). The larger size means fewer seams and more complete vein patterns, making them ideal for large countertops and wall applications. For clients seeking a seamless look and high-end custom design, super jumbo quartz slabs offer more design flexibility and are becoming increasingly popular in modern residential and commercial spaces. The following table reveals the differences between standard quartz slabs and super jumbo quartz slab.

| Feature | Super Jumbo Quartz | Standard Quartz |

|---|---|---|

| Typical Size | 3500 × 2000 mm (138"×78") | 3000 × 1400 mm (120"×55") |

| Design Advantage | Fewer seams, continuous patterns | More seams, limited continuity |

| Applications | Large islands, wall cladding, commercial spaces | Bathroom vanities, small kitchen tops |

| Production Flexibility | Requires specialized equipment and handling | Easier to process and fabricate |

Quality Control and Attention to Detail

The slabs are cut and polished using advanced equipment, with strict control over thickness and color consistency to meet project standards. Each slab is labeled with an individual serial number and barcode for easy tracking and inspection. For safe transportation, we use reinforced wooden frames and multi-layer protective packaging. Every step—from lifting and packing to securing and loading—is supervised to ensure the slabs arrive in perfect condition.

Standardized Loading to Ensure Safety

During loading, we use a two-person lifting system and custom wooden crates to protect the slabs during transportation. Our factory has extensive experience in the production, packaging, and shipping of super jumbo quartz slabs, and we can provide full support throughout the process. This batch of slabs will be used in high-end custom projects for overseas clients, including kitchen islands and large conference room feature walls. These customers have higher requirements for continuous veining and size stability, which are key advantages of the super jumbo quartz format.

Custom Orders and Global Cooperation

As a professional quartz slab factory, we have long provided global clients with high-quality custom quartz countertops and engineered slabs. We support both standard and super jumbo quartz slab options to meet different project needs. Partners from North America, Europe, the Middle East, and other regions are welcome to contact us to learn more about our products, customization options, and shipping details. We also welcome factory visits to better understand our production capabilities and delivery process.