Black Soapstone Quartz Bathroom Vanity Tops for Engineered Project

- YEYANG

- CHINA

- About 20-30 days After Order Confirmed

- 5000m2 Per Month

Collection: Quartz Bathroom Vanity Tops

Quartz Type: prefabricated quartz vanity tops

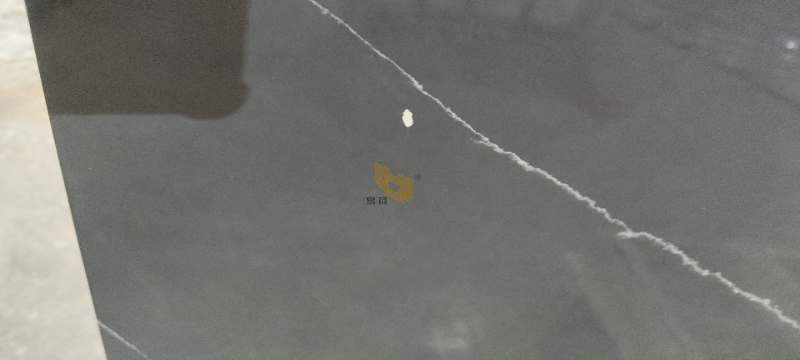

Quartz Color: Black soapstone

Yeyang Stone Support: Customizable colors, patterns, finishes, egdes, shapes, thicknesses, etc.

Yeyang Stone--Quartz Bathroom Vanity Tops

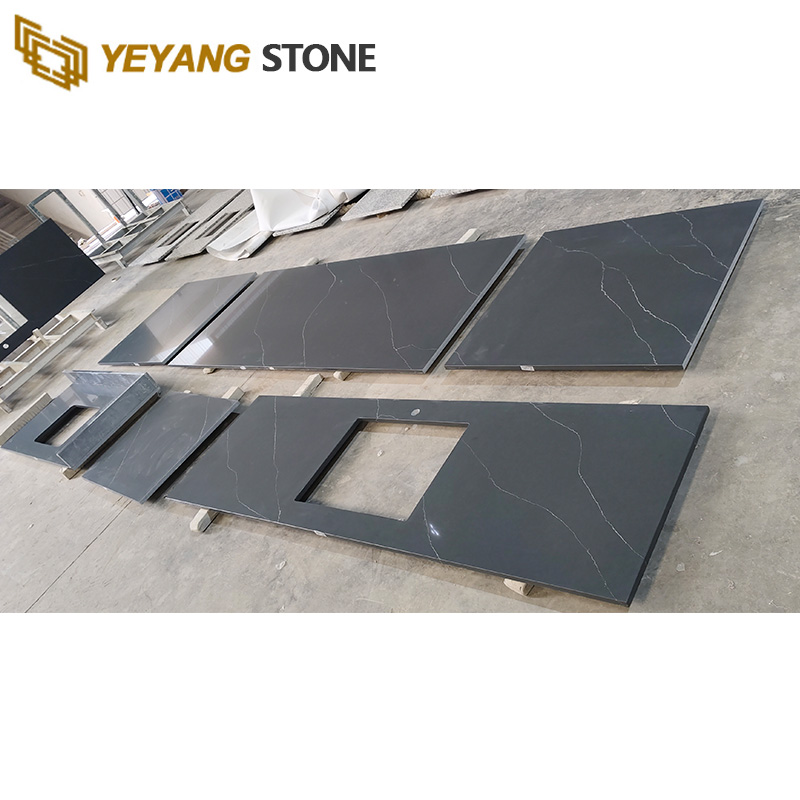

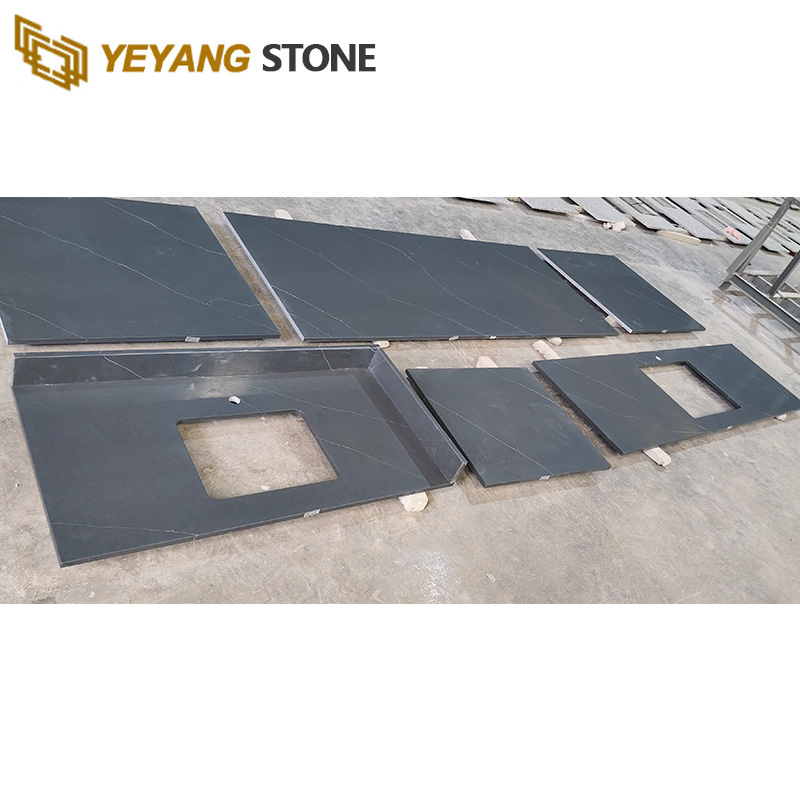

Black Soapstone Quartz Bathroom Vanity Tops for Engineered Project

Product Color: Black, White

Order Type: Engineered prefabricated quartz vanity tops

Project Application: Quartz Bathroom Vanity Tops

Project Information: This is our 1129th project order in 2025.

For this engineered project, our client selected Black Soapstone quartz slabs, crafted into bathroom vanity tops with a sleek polished finish. The deep black base, accented with subtle white veining, adds a sense of mystery and sophistication. Suitable for luxurious bathrooms or apartment renovation projects, these vanity tops offer exceptional versatility while combining striking aesthetics with durability and stability.

| Item | Details |

|---|---|

| Standard Dimensions for Countertops (inch) | Kitchen Countertops: 108" × 25.5";98" × 25.5";96" × 25.5" Island Tops: 96" × 26";108" × 26";96" × 36";72" × 36" Vanity Tops: 36" × 22";37" × 22";25" × 22";49" × 22";72" × 22" Snack Bar Tops: 12" × 78";15" × 78" |

| Edge Finishes | Straight, 1/4 Round, 1/4 Bevel, Half Bevel, Full Bullnose, Half Bullnose, Ogee, Laminated Straight, etc. |

| Surface Finishes | Polished, Honed, Brushed, Hammered, Leather, etc. |

| Lead Time | 15–25 days after order confirmation |

| Payment Terms | T/T; L/C |

| Customization | Dimensions, thickness, colors, and cutting shapes can be customized according to drawings. |

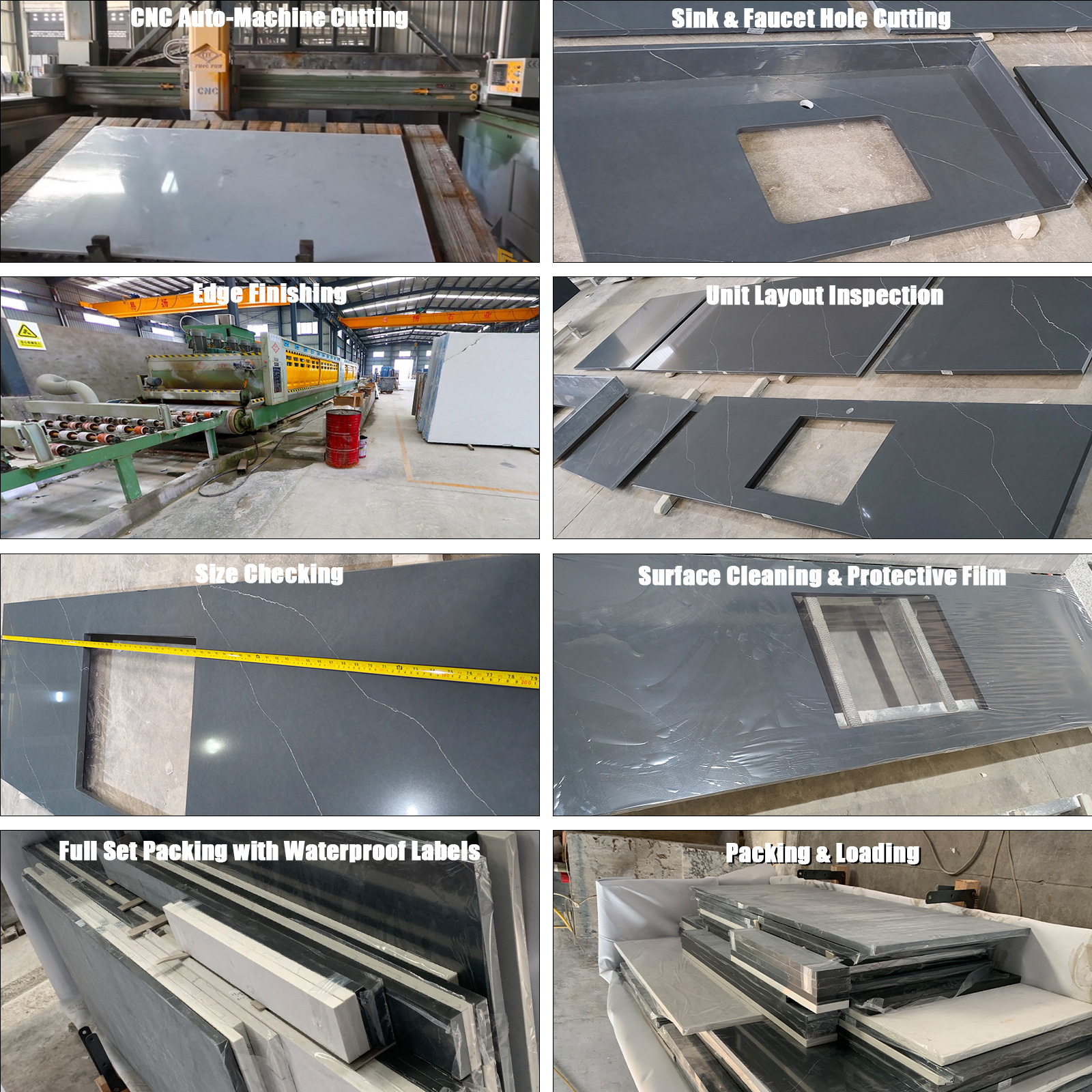

Production Process & Quality Assurance

1.Cut-to-Size Quartz Top/Slab

Each slab goes through rigorous quality control to ensure no chipping, color variation, or uneven finish. These refined details not only demonstrate the stability and durability of machine-processed quartz but also embody the modern aesthetic appeal that makes quartz countertops an ideal choice for both residential and commercial interiors.

2.Auto-Machine Cutting

Using advanced CNC cutting machines, the quartz slabs are cut into the required sizes (both quartz slabs and countertop pieces) according to digital drawings. This process includes edge trimming, corner shaping, as well as precise cutting of sink cutouts and faucet holes. Each quartz countertop is machine-cut with millimeter-level accuracy, ensuring clean edges, smooth surfaces, and a perfect fit with the project’s overall design layout.

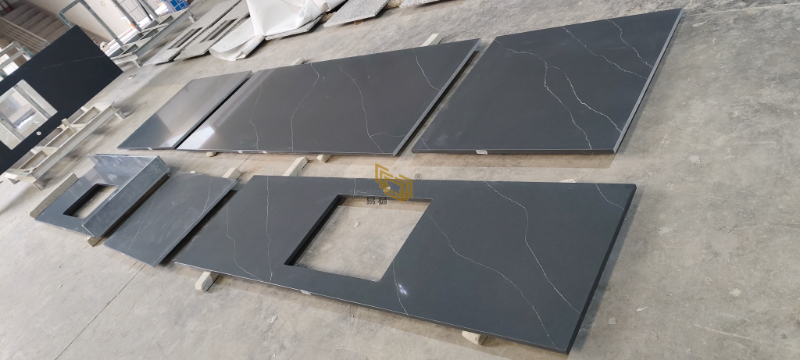

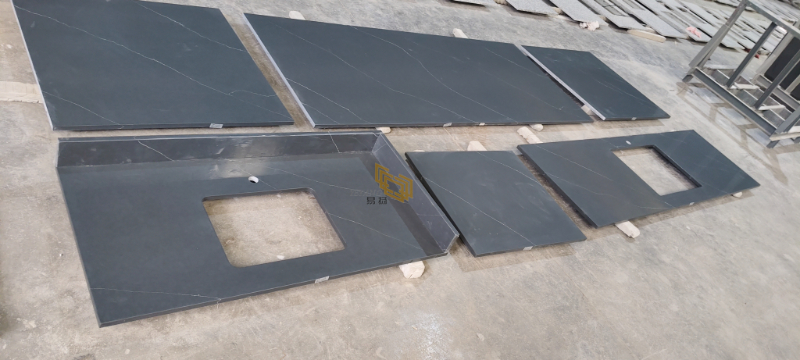

3.Unit Layout Inspection

All fabricated pieces (cut-to-size quartz slabs & countertops) are arranged and inspected as a complete set to confirm uniform thickness, color tone, and edge polish. This final check guarantees a consistent appearance and precise fit during installation.

4. Quality Inspection

All fabricated countertops undergo a detailed quality inspection before packing. Each piece is checked for accurate dimensions, flatness, and surface smoothness. Inspectors also verify the color consistency, edge finish, and overall appearance by placing the pieces together as a full set. This process ensures that every countertop meets the required fabrication standards and that all parts align seamlessly during installation.

5.Surface Cleaning & Protective Film

Before packing, all dust and residues are removed from the surface. Protective plastic film is applied or replaced to safeguard the polished surface during transport and installation.

6.Packaging & Loading

After cleaning, the finished countertops are grouped and arranged according to each project. Every piece is wrapped with corner protectors and cushioning materials to prevent scratches or impact. The sets are then securely packed into sturdy, fumigation-free wooden crates with internal supports to keep them stable during transport. Once packaged, all crates are labeled with project details and moved to the designated loading area, where they are kept upright and ready for container loading or delivery scheduling.

FAQ

1. Do you support engineering bathroom countertop projects?

Yes. We support OEM and ODM cooperation, offering flexible customization and bulk supply solutions. Our services are tailored for distributors, wholesalers, and project partners seeking stable quality and long-term collaboration.

2. Can you fabricate bathroom countertops based on project drawings?

Absolutely. We provide cut-to-size bathroom countertops strictly according to customer-provided drawings, including sink cutouts, faucet holes, edge profiles, and installation requirements.

3. How do you ensure consistency for batch bathroom countertop orders?

We take the following measures to ensure product consistency:

We keep detailed records of every color-matching formula to ensure consistency in bulk production.

For the same order, we assign experienced staff to produce both the samples and the bulk production, ensuring uniform production processes.

Once production is complete, we use the archived sample to perform strict color matching. If any color discrepancies are found, we will immediately arrange for re-production to ensure the final product meets quality standards.