Quartz Source Factory Reveals How to Tell If Your Countertop Is Up to Standard

Quartz Source Factory Reveals How to Tell If Your Countertop Is Up to Standard

Quartz countertops have risen in popularity as a choice for modern kitchens and bathrooms due to their durability, low maintenance, and design versatility. However, not all quartz surfaces on the market meet the same standards. Are you considering purchasing one of the most popular quartz countertops on the market, but concerned about how to accurately assess its quality? As a source manufacturer, we are uniquely positioned to share expert insights into identifying a high-quality quartz countertop. The following guide outlines practical checks and questions you can use to ensure that your quartz slab meets both your aesthetic expectations and functional requirements.

1. What Makes a High-Quality Quartz Countertop

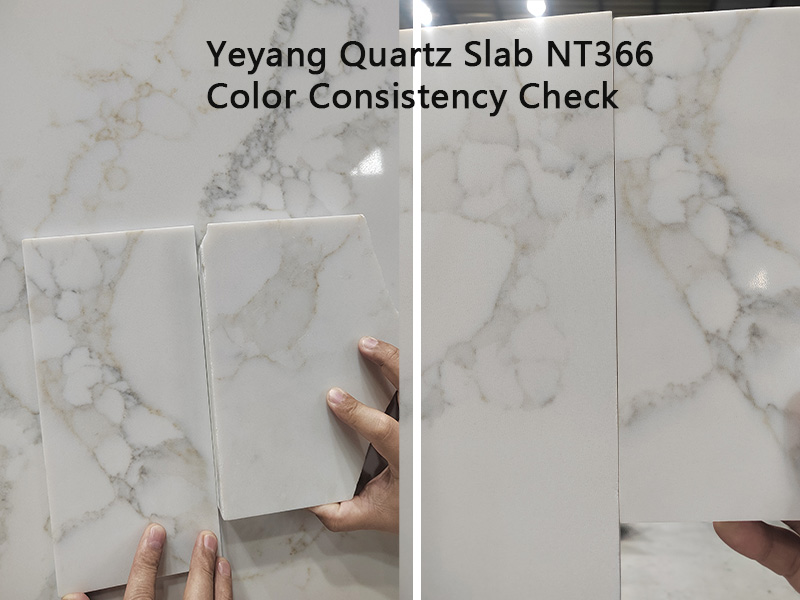

1) A high-quality quartz countertop begins with premium materials. It should consist of at least 90% natural quartz sand, combined with resin and pigment. This high quartz content gives engineered quartz both strength and stability. Look for specifications or certificates that confirm this ratio.

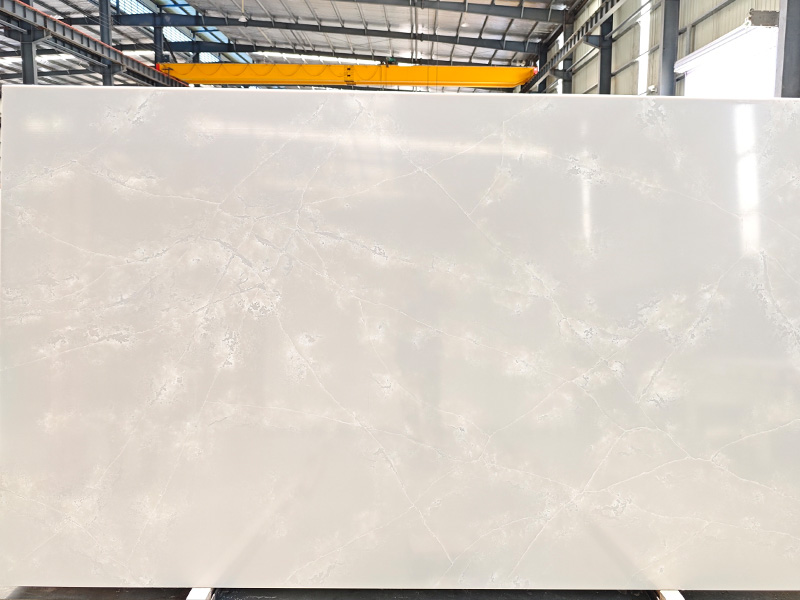

2) The surface structure should be dense and non-porous. That means no visible holes or open pores under close inspection. A true quartz slab should not absorb water or staining agents.

3) Precision in cutting and flatness of the slab is also critical. High-quality slabs demonstrate consistent thickness, usually within a tolerance of ±0.5 mm. Edges and cutouts should be clean and even, showing sharp, straight lines without chipping.

4) Finally, evaluate the pattern and color distribution. A durable quartz countertop will exhibit natural-looking veining that has depth. The coloration should be even, with no blotchy areas or unnaturally repeated patterns. A consistent pattern across multiple slabs shows controlled manufacturing.

(Yeyang matte quartz slab NT366 quality check-surface check-no visible holes or open pores)

2. Visual and Structural Checks You Can Do Yourself

1) Begin with a visual inspection under natural daylight. Run your hand gently across the surface. A smooth, polished quartz surface will feel uniform without grit or pits.

2) Turn the slab over if possible to inspect the backside. A high-quality quartz slab will show uniform density, with no filler or thin spots.

3) Check seams and edges closely, especially if you intend to order large slabs. Seams should be tight, and edges should align without overhang or misalignment that could compromise fit or aesthetics.

4) Observe the depth of pattern. High-quality quartz surface patterns should appear embedded, not simply printed on the surface. This depth effect is achieved through multi-layer printing or full-body printing methods

(Yeyang polished super quartz slab NT468 quality check-surface check-smooth surface without grit or pits)

3. Ask the Right Questions Before You Buy

1) Ask your supplier what percentage of quartz is used in the mix. Slabs with less than 90% quartz or unspecified composition may indicate a lower quality product.

2) Request certifications or laboratory test results. Thermal shock resistance, stain resistance tests, and flexural strength are particularly relevant.

3) Check if the factory can produce super jumbo quartz slabs. Access to jumbo slabs indicates a well-equipped facility with advanced processing capabilities.

4) Clarify the difference between entry-level engineered quartz and premium quartz slabs. Suppliers should label their product ranges clearly, such as warm-tone quartz or marble-look quartz.

4. Factory Insight: What We Check Before Shipping

Before any quartz slab leaves our production line, it goes through a rigorous quality control process.

1) We check color consistency between slabs, examining them under daylight conditions.

2) Each slab is measured for thickness uniformity and inspected with straight edges to ensure flatness.

3) Edges and cutouts are examined for precision; even small deviations can indicate processing issues that may affect the countertop during installation.

4) Finally, we conduct a final surface inspection to confirm there are no chips, pits, scratches, or other imperfections. Once the slab passes these checks, it is securely packaged and prepared for shipping.

This attention to detail ensures that every durable quartz countertop delivers on both aesthetics and performance.

5. Conclusion

Choosing a high-quality quartz countertop requires understanding what to look for in materials, appearance, and manufacturing. From material composition and density to precision cutting and quality control, each element affects final performance. By selecting a reliable source or direct manufacturer, you ensure that your quartz countertop meets the standards you expect in both form and function.

If you are sourcing quartz slabs for residential or commercial projects, we encourage you to request samples or inquire about our engineered quartz options, including marble-look slabs and warm-tone quartz surfaces. Contact us to learn more about our factory’s production capabilities, certification details, and customization services. Let our expertise help you secure the right countertop for your next project.