Galaxy Black Quartz Slab Quartz Countertop for Sophisticated Interiors

- YEYANG

- CHINA

- About 20-30 days After Order Confirmed

- 5000m2 Per Month

Galaxy Black Quartz Slab Quartz Countertop for Sophisticated Interiors--Premium Black Quartz Countertop for Stunning Elegance.

Yeyang Stone--Quartz Kitchen Countertop

Galaxy Black Quartz Slab Quartz Countertop for Sophisticated Interiors

Galaxy Black Quartz Slab Quartz Countertop Description:

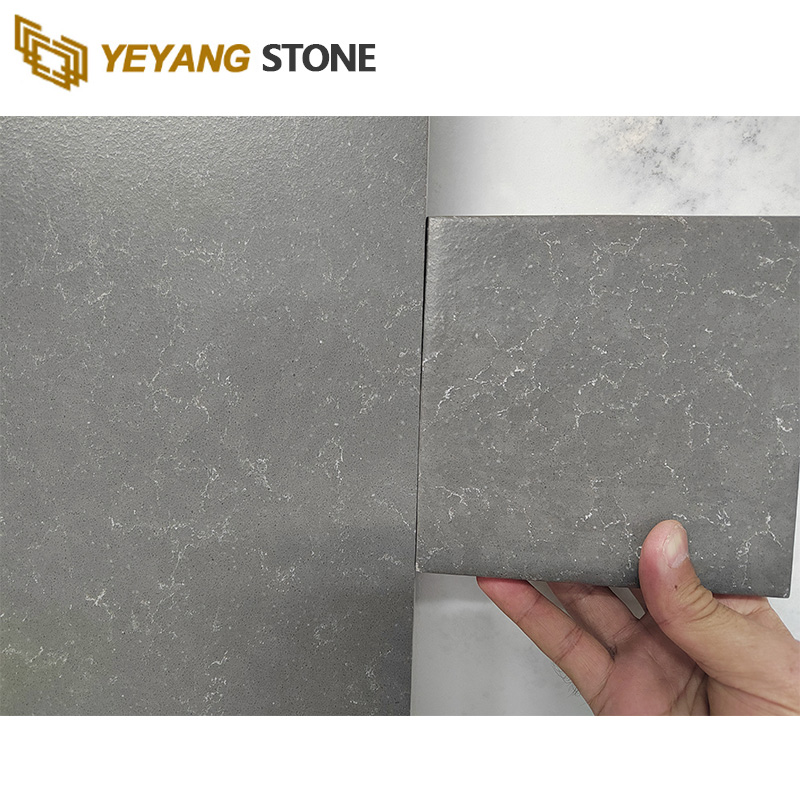

The galaxy black quartz slab is a premium choice for those seeking a sophisticated, bold, and luxurious surface. This black quartz countertop boasts a sleek, glossy finish that brings modern elegance to any space. Whether used in kitchens, bathrooms, or commercial spaces, this quartz slab provides unmatched durability and a stunning visual appeal. Its deep black color is speckled with subtle, glittering patterns that mimic the beauty of the night sky, creating a striking centerpiece for any design.

Product Data:

material: | Galaxy Black Quartz Slab |

slab: | 2400up x 1200up x 15mm, 2400up x 1200up x 20mm, 2400up x 1200up x 30mm etc. |

tile: | 305 x 305 x 10mm, 305 x 610 x 10mm, 610 x 610 x 10mm etc. |

countertop: | Rectangular Kitchen Countertop: 26" x 96", 26" x 98", 28" x 108" Curved Kitchen Countertop: 36" x 78", 39" x 78", 28" x 78" Kitchen Table Top: 72" x 39", 96" x 39"; Kitchen Bar Top: 12" x 78", 15" x 78". Normal Thickness: 3/4", 1 1/2", 1 3/16" Edge Finished: Eased, Beveled, Bullnose, Ogee, Cove, Laminated and non-laminated edge etc. |

finish: | polished, honed, antique, sandblasted, etc. |

packing: | foam inside + strong seaworthy wooden crates with reinforced straps outside. |

Elegant Aesthetic: The galaxy black quartz slab offers a refined, polished surface with shimmering patterns that make it a standout choice for modern, minimalist, or luxury spaces.

Durability: Unlike natural stone, this black quartz countertop is non-porous, resistant to stains, and extremely durable, making it an ideal choice for high-traffic areas.

Low Maintenance: With no sealing required, this quartz slab is easy to clean—simply wipe it down with mild soap and water.

Versatility: The deep, dramatic color of the galaxy black quartz slab complements a variety of interior styles, from contemporary to industrial.

Galaxy Black Quartz Slab Quartz Countertop Application:

Kitchen Countertops: Create a bold statement with a black quartz countertop that’s perfect for food prep areas, offering both style and practicality.

Bathroom Vanities: Bring elegance to your bathroom with a Galaxy Black Quartz Slab for sleek, luxurious vanity tops.

Commercial Spaces: Ideal for high-end retail environments, restaurants, and hotels, the Galaxy Black Quartz Slab ensures a polished, upscale look.

How is Galaxy Black Quartz Slab Made?

The process of manufacturing a galaxy black quartz slab such as black quartz countertop or black quartz vanity tops, involves a series of detailed steps to ensure high quality and consistency. Here's a breakdown of the entire process:

1. Raw Material Collection:

Acquire necessary raw and auxiliary materials, such as glass, quartz, and resin, essential for producing quartz worktops and grey quartz countertops.

2. Material Selection:

Utilize fans and iron removal equipment to eliminate impurities and iron filings.

Manual selection to further ensure the purity of materials, crucial for maintaining the quality of quartz natural stone.

3. Ingredients Preparation:

Transport selected materials into a mixing system.

Use a non-gravity mixer to fully blend the materials, addressing issues of color inconsistency and particle size.

Transfer the mixed materials to the corresponding batching bin, where the batching system automatically measures them during production.

4. Stirring and distribution:

Thoroughly mix unsaturated polyester resin, pigments, additives, and granular powder.

Transfer the mixed material through a conveyor belt to a distribution car.

The distribution car spreads the material evenly into the mold frame.

5. Vacuum High-Frequency Vibration Pressing Slab:

Transfer the material to pressing equipment.

Vibrate and press the material under vacuum conditions of -0.1MPa, a critical step for all types of quartz worktops.

6. Heat Curing and Shaping:

Heat and shape the pressed blank in a curing furnace at 85-110℃, ensuring the durability of grey quartz countertops.

7. Thickness Setting and Polishing:

Cool the solidified blank for 24 hours.

Set the thickness using thickness setting equipment.

8. Polishing:

Water polish the set thickness using a 20-head polishing machine.

Achieve a gloss finish of 40-70°, depending on specific needs, suitable for gray quartz vanity tops.

9. Inspection:

Inspect the board for appearance quality.

10. Cutting:

Cut the product to the required size using vertical and horizontal cutting and bridge cutting equipment.

11. Packing and Storage:

Air-dry the cut products.

Pack and store the products in the warehouse.

About Us:

◆Yeyang specialized in manufacturing & exporting Marble Kitchen and Bathroom Countertops/vanity tops/island tops for residential and commercial projects at a good price, We are the leading natural granite & quartz countertop exporter from China.

◆As a manufacturer, we are competitive in cost, quality, and fast delivery. Meanwhile, as local well known professional good support from the other 20 family's factories, more than 100 cooperative factories.

◆Yeyang stone factory has been joined the stone fair in Verona fair, USA fair coverings in Atlanta, Xiamen stone fair, and so on. We hope to make long good cooperation relationship in stone fairs by high-quality products, professional service, and competitive prices. We have more than 100+ International import partners, we always thank all old and new customers for their support and trust.

◆Please visit our contact page to receive a quote or ask any questions you might have. Welcome to come to consult and negotiate, let us mutually benefit!

Paching and loading:

The foam inside & strong seaworthy wooden crates with reinforced straps outside.

Our More Certification:

We have obtained multiple certifications and a quality inspection certification.

Yeyang stone has more than 15 years of experience in stone industry manufacturing.